electronic products machinery pcb line machine smd bga rework

station Machine

| Power Supply | AC 220V±10% 50/60Hz |

| Total power | Max5300w |

| Heater power | Upper temp.zone 1200W,second temp.zone 1200W,IR temp.zone 2700W |

| Electric material | Driving motor+PLC smart temp.controller+color touch screen |

| Temperature control | independent temp.controller,the precision can reach ±1℃ |

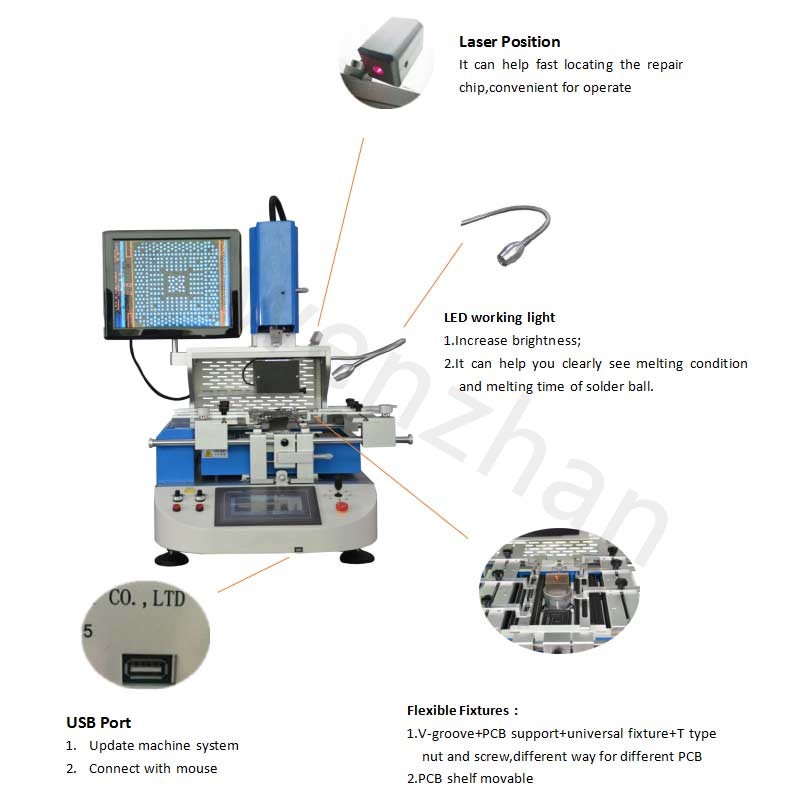

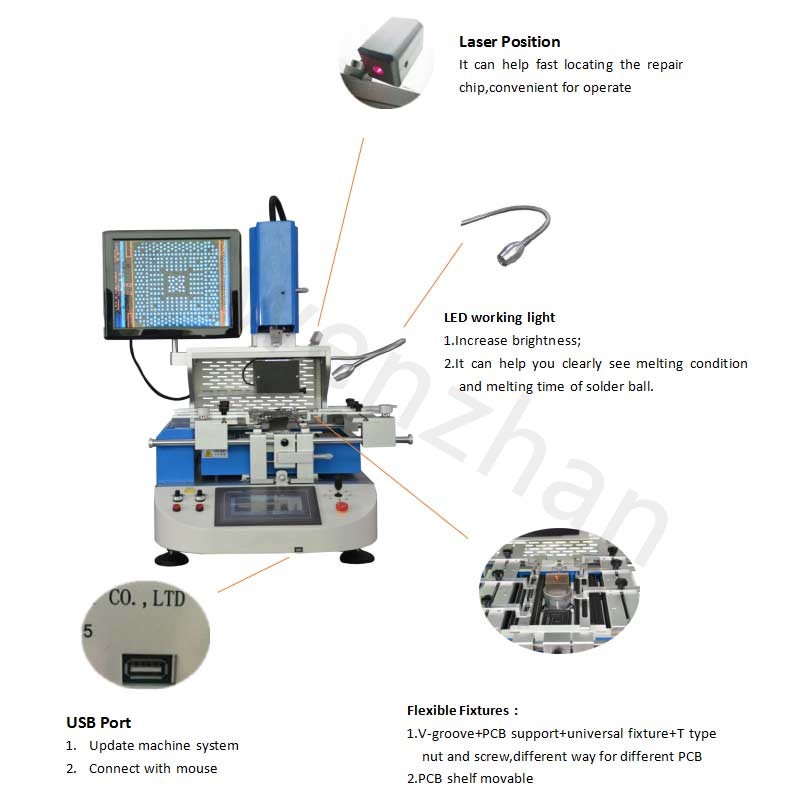

| Locating way | V shape slot,PCB support jigs can adjust,laser light do fast

centering and position |

| PCB size | Max 450×390mm Min 10×10 mm |

| Applicable chip | Max 80×80mm Min 1×1 mm |

| Overall dimension | L650×W630×H850mm |

| Temperature Interface | 1pcs |

| Weight of machine | 60kg |

BGA rework station is a specialized equipment used in the

electronic manufacturing industry for reworking Ball Grid Array

(BGA) components. It enables the removal and replacement of BGA

components on printed circuit boards (PCBs), allowing for repairs

and modifications to be made.

The BGA rework station consists of several key components,

including a heater, a temperature control system, a microscope, and

a vacuum system. The heater is used to heat the BGA component and

the PCB, allowing the solder to melt and the component to be easily

removed. The temperature control system ensures that the

temperature is controlled accurately and precisely, minimizing the

risk of damaging the components or the PCB due to excessive heat.

The microscope is used to inspect and align the BGA component

during the rework process. The vacuum system is used to hold the

BGA component in place during the reflow process and ensure a

proper connection between the component and the PCB.

The basic principle behind the BGA rework station is the reflow

soldering process. BGA components are attached to the PCB using

solder balls underneath the component. During rework, the BGA

rework station heats up the component and the PCB to a specific

temperature that melts the solder, allowing the component to be

easily removed. After the removal of the component, the solder pads

on the PCB are cleaned and prepared for the replacement component.

BGA Rework station The replacement component is aligned with the

solder pads on the PCB using the microscope, ensuring accurate

positioning. Once aligned, the component is placed on the PCB and

heated again. The solder reflows, creating a strong and reliable

connection between the component and the PCB. The vacuum system

helps to hold the component in place during the reflow process,

ensuring proper alignment and preventing any movement of the

component.

During the entire process, it is crucial to maintain an accurate

and controlled temperature to prevent damage to the components or

the PCB. Excessive heat can cause thermal stress, leading to

component or PCB failure. The BGA rework station's temperature

control system ensures that the temperature is carefully regulated

throughout the rework process, minimizing the risk of damage.

In conclusion, BGA rework station is a specialized equipment used

for the removal and replacement of BGA components on PCBs. It

utilizes the reflow soldering process and incorporates various

components like a heater, a temperature control system, a

microscope, and a vacuum system. The station allows for efficient

and accurate rework of BGA components, enabling repairs, upgrades,

or modifications in the electronic manufacturing industry.

BGA Rework Station

Model:WDS-620

1. Automatic&Manual operation system

2. 5 million CCD camera optical alignment system mount

precision:±0.01mm

3. MCGS touch screen control

5. Laser position

6. Repair success rate 99.99%

Temperature Control System

1. 8 segment temperature can be set at same time,It can save

thousands of groups of temperature curves;

2. Large area IR heater preheating up for the bottom of PCB to

avoid PCB deformation during working;

3. Adopted high precision K-type thermocouple close-loop control

and PID parameter self-setting system,temperature precision control

±1℃;

4. Provide many kinds of titanium alloy BGA tuyere can be rotated

in 360 degree for easy installation;

Top heater(1200w)

1.Air outlet design ensure focus heating,effective

to increase success rate;

2.Top air reflow is adjustable,suit for any chips;

3.Nozzle equipped different size for different chip

| WZ-580 | WZ-620 | WZ-650 | WZ-750 |

| Power | AC 220V±10% 50Hz | AC 220V±10% 50/60Hz | AC 110V / 220V±10% 50/60Hz | AC 110V / 220V±10% 50/60Hz |

| Overall dimension | L500mm*W590mm*H650mm | L650×W630×H850mm | L 600*W 640*H 850mm | L830×W670×H850mm |

| PCB size | Max 400mm*370mm Min 10mm*10mm | Max 450×390mm Min 10×10 mm | Max 400mm*370mm Min 10mm*10mm | MAX 550×480mm MIN 10×10mm( customizable ) |

| BGA chip size | Max 60mm*60mm Min 1mm*1mm | Max 60mm*60mm Min 1mm*1mm | MAX 70*70mm -MIN 1*1 mm | Max 60mm*60mm Min 1mm*1mm |

| PCB thickness | 0.3-5mm | 0.3-5mm | 0.3 - 5mm | 0.5-8mm |

| Weight of machine | 40KG | 60kg | 60KG | 90kg |

| Warranty | 1 year | 1 year | 1 year | 1 year |

| Total power | 4800W | 5300w | 6400W | 6800W |

| Usage | Repair chips / phone motherboard etc | Repair chips / phone motherboard etc | Repair chips / phone motherboard etc | Repair chips / phone motherboard etc |

| Electrical material | Touch screen+Temperature control module+PLC control | Driving motor+PLC smart temp.controller+color touch screen | Driving motor + smart temp. controller + color touch screen | Touch screen+Temperature control module+PLC control |

| Location way | V-shape card slot+Universal jigs | V-shape card slot+Universal jigs | V-shape card slot+Universal jigs | V-shape card slot+Universal jigs |

| MODEL | WZ-580 | WZ-620 | WZ-650 | WZ-750 |

| Power | AC 220V±10% 50Hz | AC 220V±10% 50/60Hz | AC 110V / 220V±10% 50/60Hz | AC 110V / 220V±10% 50/60Hz |

| Overall dimension | L500mm*W590mm*H650mm | L650×W630×H850mm | L 600*W 640*H 850mm | L830×W670×H850mm |

| PCB size | Max 400mm*370mm Min 10mm*10mm | Max 450×390mm Min 10×10 mm | Max 400mm*370mm Min 10mm*10mm | MAX 550×480mm MIN 10×10mm( customizable ) |

| BGA chip size | Max 60mm*60mm Min 1mm*1mm | Max 60mm*60mm Min 1mm*1mm | MAX 70*70mm -MIN 1*1 mm | Max 60mm*60mm Min 1mm*1mm |

| PCB thickness | 0.3-5mm | 0.3-5mm | 0.3 - 5mm | 0.5-8mm |

| Weight of machine | 40KG | 60kg | 60KG | 90kg |

| Warranty | 1 year | 1 year | 1 year | 1 year |

| Total power | 4800W | 5300w | 6400W | 6800W |

| Usage | Repair chips / phone motherboard etc | Repair chips / phone motherboard etc | Repair chips / phone motherboard etc | Repair chips / phone motherboard etc |

| Electrical material | Touch screen+Temperature control module+PLC control | Driving motor+PLC smart temp.controller+color touch screen | Driving motor + smart temp. controller + color touch screen | Touch screen+Temperature control module+PLC control |

| Location way | V-shape card slot+Universal jigs | V-shape card slot+Universal jigs | V-shape card slot+Universal jigs | V-shape card slot+Universal jigs |