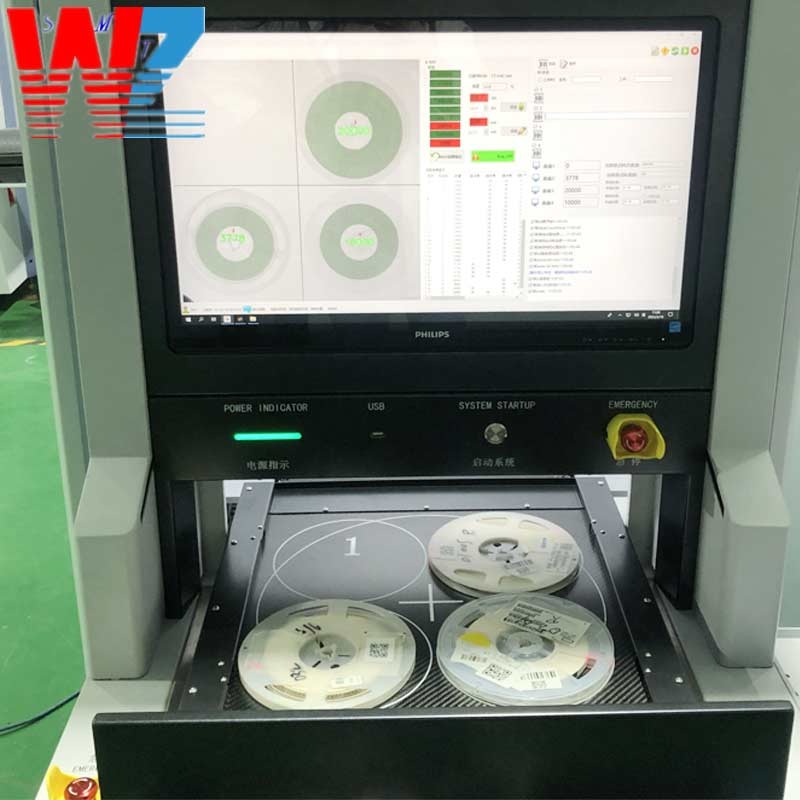

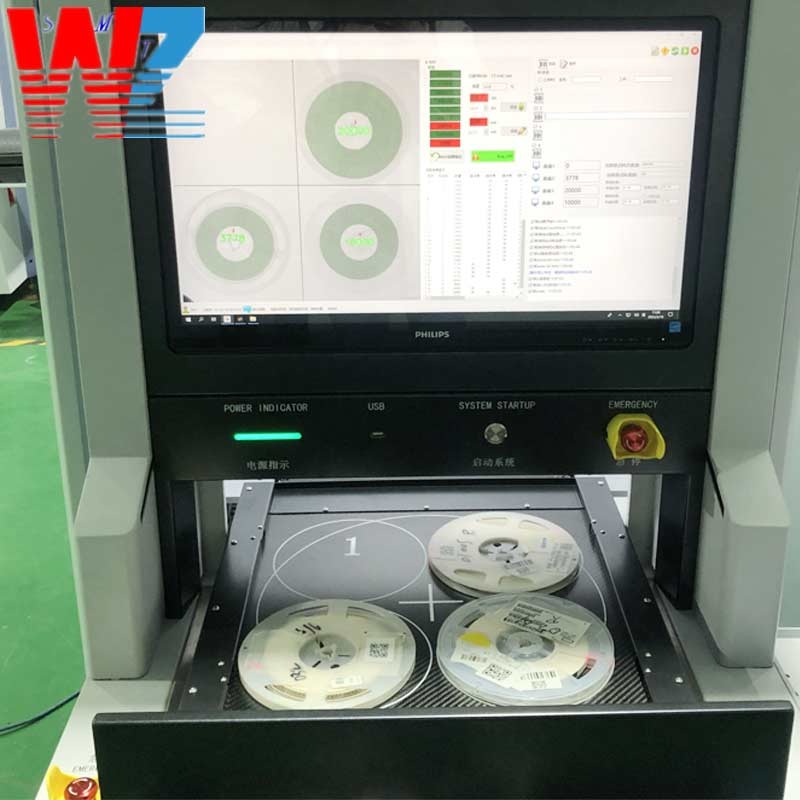

Electronics production machinery SMT X-ray intelligent counter

Automatic Electronic Smt X-ray Reel Components Counting Machine

X-ray Counting Systems X-ray intelligent counter

The X-ray intelligent counter is a sophisticated device used for

counting and detecting objects in X-ray images. It utilizes

advanced image

processing algorithms and artificial intelligence to accurately

identify and count specific items or substances within X-ray scans.

The counter is commonly employed in various industries, such as

security, healthcare, and manufacturing, where precise counting and

detection

of objects is crucial.

The X-ray intelligent counter offers several key functionalities:

1. Object Detection: The counter can detect and identify specific

objects or substances based on predefined criteria. For example, in

a security setting, it can identify weapons, explosives, or

contraband items within luggage or packages.

2. Object Counting: The counter accurately counts the number of

instances of a particular object within an X-ray image. This

feature is valuable in scenarios where inventory management or

quality control is essential. It can count items like pills in

pharmaceutical manufacturing or components in electronic assembly

lines.

3. Anomaly Detection: The counter can identify anomalies or

irregularities within X-ray scans. It compares the scanned image

with a reference model or database to flag any deviations.

4. Image Analysis: The counter performs detailed analysis of X-ray

images, extracting relevant information and providing visual

representations of the scanned objects. It can generate heat maps,

highlight specific areas of interest, or superimpose labels to aid

in interpretation.

Using the X-ray intelligent counter typically involves the

following steps:

1. Image Acquisition: Capture or import the X-ray image or scan

that needs to be analyzed. This can be done using compatible X-ray

equipment or by importing digital scans.

2. Preprocessing: Prepare the image for analysis by applying

necessary adjustments, such as noise reduction, contrast

enhancement, or image calibration. This step ensures optimal image

quality for accurate detection and counting.

3. Object Selection and Configuration: Define the specific objects

or substances to be detected and counted. This involves configuring

the counter with the appropriate parameters, such as size, shape,

or density thresholds, depending on the target objects.

4. Analysis and Reporting: Initiate the analysis process, allowing

the counter to detect, count, and analyze the objects within the

X-ray image. The results can be displayed in real-time or saved for

later review. Generate reports summarizing the findings if

required.

Interpretation and Decision-making: Review the analyzed results and

interpret the information provided by the counter. Make informed

decisions based on the detected objects, counts, and any flagged

anomalies or irregularities.

Use requirements: After the direct counting of the X-RAY

intelligent counting machine is completed, the result data of the

counting will be uploaded to the digital control system for

updating.

And application occasions:

① WO material return ② single LPN inventory ③ initial

inventory/double inventory.

Docking scheme and process:

1.Business type initiated by counting machine

The counting machine adds checked items in the operation interface;

High-line mode/WO material return/count sheet count point/single

LPN count

① Offline model

No connection with IMS system, direct counting

② WO Material Return

Only applicable to the operation scenario of WO material return:

LPN must be in "push status"

③ Counting sheet count

Applicable to the "custom count" function of IMS;

LPN must be in the "locked status" of the count sheet

④ Single LPN count

Correction of the number of single LPN in the "library" state

2.The point modem calls the IMS interface and transmits the

following information to the IMS:

LPN number, business type code

3.LPN verification:

IMS judges whether the current status of LPN is consistent with the

selected service type

Verification passed: IMS returns the OK message,

Point data machine starts counting and enters the next step

Verification failed:

IM5 returns NG information, and the counting machine displays in

the pop-up box on the operation interface

IMS error message, stop count

4.The counting machine returns the counting result data: LPN number

and counting quantity

IMS updates the remaining number of LPN, returns the result

information, and prompts the IMS data update result on the computer

interface

Offline mode function introduction

1. The equipment can be used without connecting to the digital

control system to realize direct counting in offline mode.

2. The offline mode can realize full automatic counting, full

automatic label printing, and full automatic count report

generation.

Offline mode label printing rules

other machine

We are smt support provider for smt machine parts and equipment

.such as reflow solder oven, Wave Soldering Machine, Pick and Place

Machine, SMT PCB Printer, SMT AOI SPI Machine, SMT Reflow Oven, PCB

conveyor , smd counter ,loader & unloader machine ,nozzle / feeder

, feeder storage cart smt reel rack , smt grease , solder paste

mixer, KIC thermal profiler,smt tape ,SMT Assembly line and so on .

wenzhan Techonologies Co.,Ltd

In 2009, Shenzhen wenzhan Technology Co., Ltd. was established to

build a more timely and effective communication platform, and

realize the company's service tenet of serving leading

customers.The engineers of the company are professional technicians

who have been certified by the original factory for more than 10

years. They always adhere to the value of putting the interests of

customers first, and provide customers with high-quality equipment

accessories, consumables, fixtures and technical support services.

In order to effectively reduce the cost of customers, the company

set up a machining plant, and changed most of the feeder parts to

self-produced parts, so as to ensure sufficient inventory and

reduce the cost of customers at the same time.

Why Choose Us?

It is precisely because wenzhan technology has the following

advantages over the same industry that

more and more customers choose wenzhan as their preferred supplier.

1. Professional pre-sales advice support

2. Excellent after-sales technical service

3. Flexible payment and return policy

4. One stop solution for SMT accessories

5. Stock in the factory with sufficient stock and fast delivery