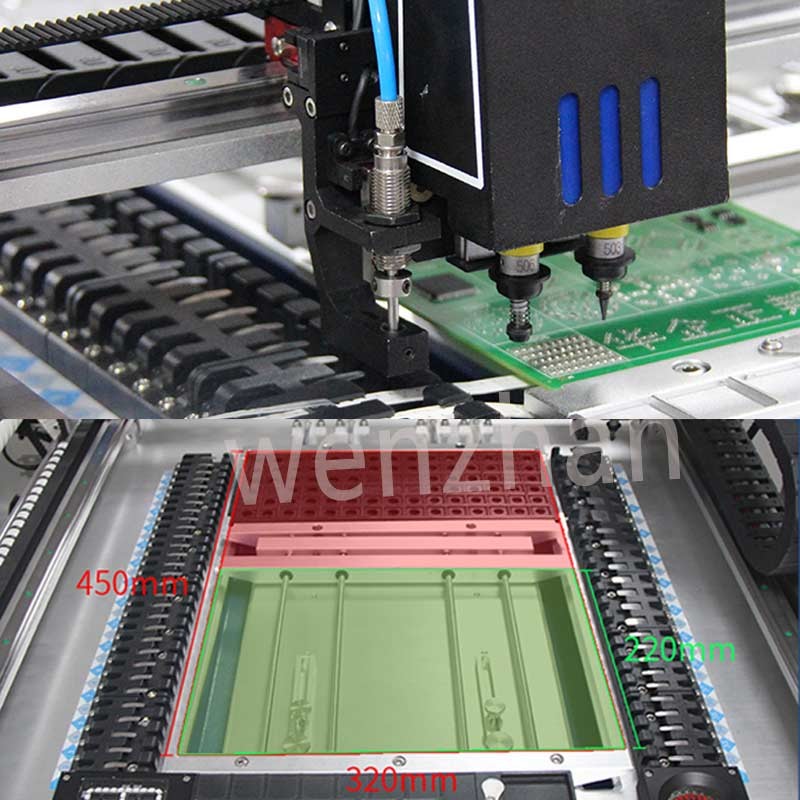

SMT Line Automatic 2 Head High Drive Mini Desktop LED Pick And Place Machine

The Desktop Pick and Place Machine is a compact and versatile solution for small-scale electronics assembly and prototyping. Designed to cater to the needs of hobbyists, small businesses, and electronics enthusiasts, this machine offers a user-friendly and accessible way to automate the placement of surface mount components on printed circuit boards (PCBs).

Key Features:

1. Compact Design: The Desktop Pick and Place Machine is designed to fit comfortably on a standard workbench or desktop, making it an ideal choice for small-scale, space-constrained environments..

2. High Placement Accuracy: Despite its compact size, the machine is capable of placing components with remarkable precision, typically achieving an accuracy of ±0.1 mm or better, ensuring reliable and consistent assembly.

3. Component Compatibility: The machine supports a wide range of component types, including resistors, capacitors, ICs, and other surface mount devices, allowing for a diverse range of assembly projects.

4. Multiple Feeders: The Desktop Pick and Place Machine is equipped with multiple component feeders, allowing for the simultaneous loading of different component types, improving workflow efficiency.

5. User-Friendly Interface: The machine's intuitive control panel and accompanying software make it easy for users to set up, program, and operate the system, even for those with limited experience in electronics manufacturing.

6. Automated Placement: The machine's pick-and-place mechanism automates the tedious task of manually placing components, reducing the risk of human error and improving overall productivity.

7. Affordable and Accessible: Compared to larger, industrial-grade pick and place machines, the Desktop Pick and Place Machine is designed to be more affordable and accessible to a wider range of users, making it a cost-effective solution for small-scale electronics assembly.

Usage Instructions:

1. Set up the Machine: Carefully unpack the Desktop Pick and Place Machine and secure it to a stable workbench or desktop. Ensure that all the necessary components, such as the control unit and power supply, are properly connected.

2. Load the Component Feeders: Carefully load the machine's component feeders with the appropriate parts, ensuring that the components are properly oriented and secured.

3. Prepare the PCB: Place the printed circuit board on the machine's work surface, aligning it with the placement area.

4. Configure the Placement Program: Utilize the machine's control panel or accompanying software to input the specific placement program, adjust parameters, and calibrate the machine for the desired project requirements.

5. Start the Placement Process: Initiate the placement process by pressing the appropriate controls on the machine. The Desktop Pick and Place Machine will automatically pick up the components from the feeders and place them on the PCB with high precision.

6. Monitor the Process: Closely observe the machine's operation, checking for any errors or issues that may arise during the placement process. Adjust settings or troubleshoot as needed to maintain optimal performance.

7. Unload the Assembled PCB: Once the placement process is complete, carefully remove the assembled PCB from the machine, ensuring that the components are securely in place.

8. Maintain the Machine: Clean, inspect, and perform any necessary maintenance on the Desktop Pick and Place Machine to ensure its continued reliable operation and longevity.

By leveraging the capabilities of the Desktop Pick and Place Machine, hobbyists, small businesses, and electronics enthusiasts can streamline their electronics assembly workflows, improve quality, and explore more complex projects with greater ease and efficiency.

| Model | WZ-3245TS |

| Mounting Numbers | 2PCS |

| Mounting Precision | 0.025mm |

| Mounting Angle | 0~360° |

| Mounting Speed | 5000pcs/hour |

| Suction Nozzle Type | Juki Series Nozzle |

| Applicable Element | RC(0402,0603,0805,1206 etc) |

| LED Lamp Beads(0603,0805,3014,5050 etc) |

| Chip(SOT,SOP,QFN, BGA etc) |

| SMD Height | ≤5.5mm(Customize ≤11mm) |

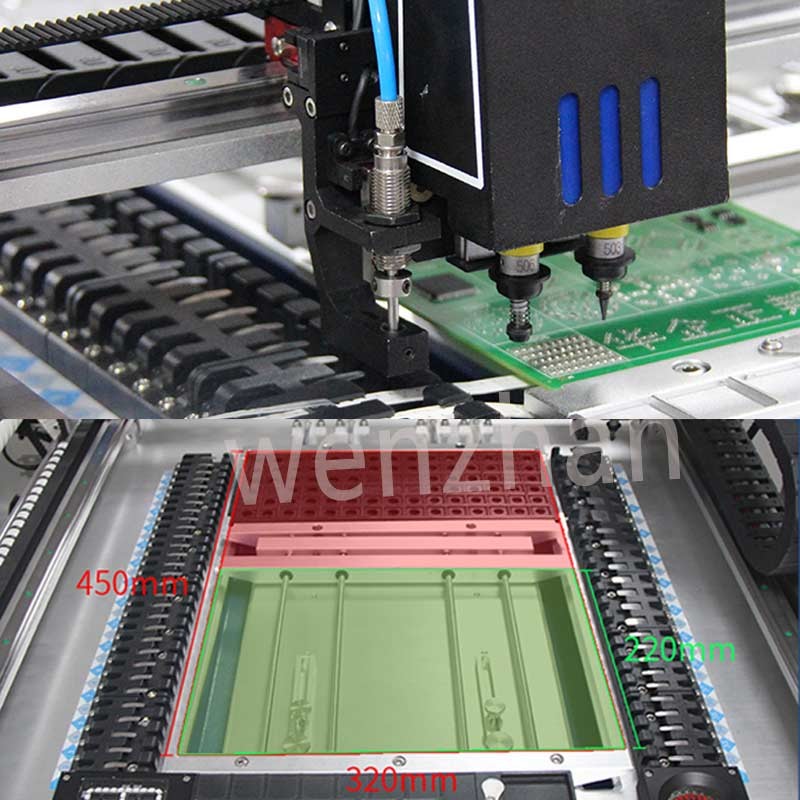

| PCB Minimal Size | 10x10mm |

| PCB Maximum Size | 320x450mm |

| PCB Thickness | S2mm |

| Components Wheel Type | 8mm,12mm,16mm,24mm,32mm |

| Front lC Location | 10pcs |

| Back lC Tray | 1pc |

| Vibration Feeder | WZ Customized Feeder(Optional) |

| X/Y Axis Moving Range | 430x530mm |

| Z Axis Moving Range | 10mm |

| Z Axis Rotation Angle | 0~360° |

| Visual Camera | CCD High-definition Camera |

| Numbers of Visual | Parts Camerax3,PCB Camerax1 |

| Recognition Capability | MAX.22x22mm |

| PC System | Microsoft WIN7 |

| Operational Software | R&D |

| Compatible File Format | CSV .TST .Format |

| Program Method | Support Online and Offline Ways |

| Air Pressure | 0.4Mpa |

| Vacuity Degree | -66kpa |

| Power | -AV220V+10% 50H |

| Power Supply | 150W |

| Main Engine Outline Size | L830xW730xH375mm |

| 1#Materials Feeder Outline Size | L235xW700xH245mm |

| Weight | 56KG |